Make In India

(Joining Hands with Atmanirbhar Bharat Abhiyaan (Self-reliant India Mission)).

Stygon Aviation and Defence provides distinguished services in support of this vital national program

through R&D, manufacturing, and testing of advanced electronic equipment and systems.

Overview

Manufacturing industry is undoubtedly backbone of the economy for a nation striving to become trillion-dollar economy. The sector has gone through many advancements through the years and has enjoyed economic booms and survived downturns. Today’s technological advances and third-party logistics outsourcing are transforming the industry further. The increased international reach and improved communications provide the manufacturing industry with a long list of cost savings and efficiencies. The manufacturing industry, along with other sectors of the economy, is able to innovate thanks to technology. In conjunction with the ‘Make In India’ initiative, Stygon aims to become one of the trusted Indian manufacturers of electronics used in airport, commercial and military systems. Stygon with its vision to design, manufacture, integrate, upgrade, repair, and overhaul both military and commercial electronics strives to cover entire spectrum with an aim to provide single point solution. The manufacturing unit is located within Manesar industrial complex (Haryana, India) at Stygon’s 65,000 sq. ft. state-of-the-art facility.

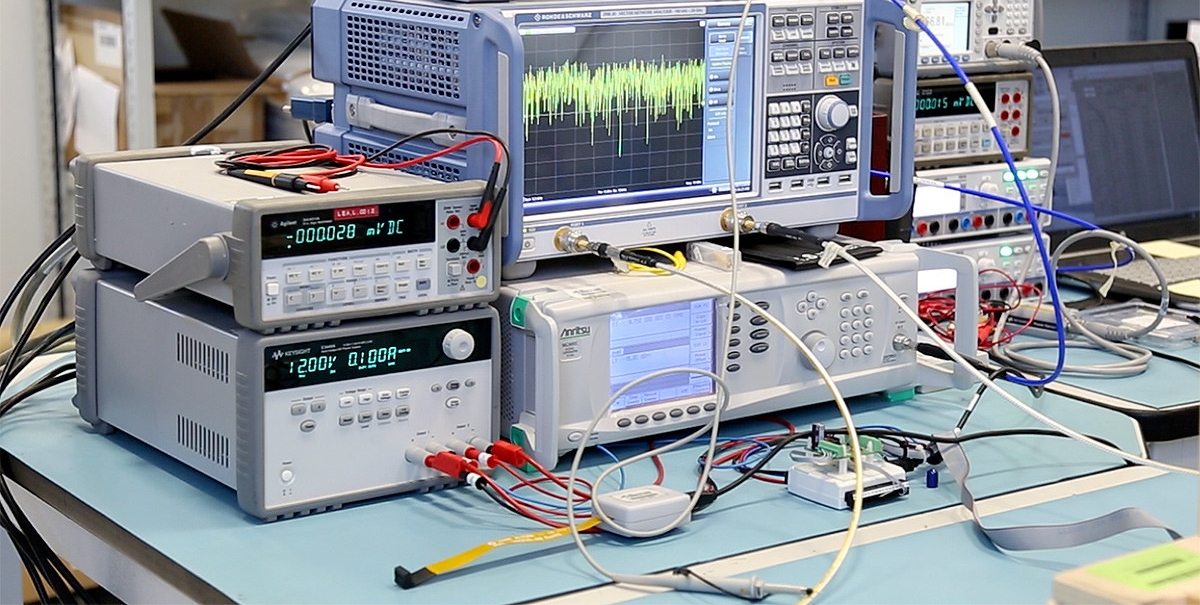

Research & Development

Stygon caters for product-related research, development, and testing services that are directly aligned with “Atmanirbhar Bharat” and “Make In India” initiatives. With due diligence, the organizational philosophy revolves around creation of in-house expertise in design and development of integrated hardware and software solutions. At Stygon all indigenous products are put through rigorous testing phases, including specialized vibration testing for equipment to be installed in military environments.

Technology Revolution

Technological advancements have brought radical changes in the industry’s profit making and operations. Faster access to information with easier and more efficient ways to use data and analytics equip the industry with necessary tools to fathom new possibilities in more territories.

Within the manufacturing industry’s inner circle, the advancements that are happening in the industry right now are called the fourth industrial revolution or Industry 4.0, referring to the closer working relationship of man and machine. This means that humans and machines share the responsibilities within the factory, not separately but in harmony. At Stygon, this is not a statement but part of work culture.

Engineering Processes

According to Vollmann (1996) todays industrial revolution is characterised by a massive explosion of information and a technological quantum leap, with consequent increases in the power and flexibility of manufacturing technology, processes, and organisation. It can be seen that the level of competition is increasingly shifting for the effective management of operations to the efficient and effective management of change. Enterprises have to continuously change and develop their performance in order to survive. Consequently, in addition to being efficient and effective in the current processes, companies have to continuously develop their capabilities for change management. At Stygon Aviation & Defence, we aim to provide tailor-made solutions to respond to your service’s needs, optimizing cost and flexibility to contribute to the improvement of the competitiveness of our clients.